© 2019 Directorate of Standardisation. All rights reserved

DIRECTORATE OF STANDARDISATION STUDY MATERIAL FOR COURSES CONDUCTED AT INSTITUTE OF STANDARDS TRAINING PUNE MAY 2001 CONTENTS

- Standardisation

- Introduction

- Dte. and Cells

- Standardisation Documents

- Harmonisation

- Codification

- Introduction

- Methodology of Codification

- IIG System

- Control of Variety

- IIG Formats

- Defence Standardisation Networks

- ISO 9000

- COTS

STANDARDISATION

INTRODUCTION

1.01 Since the history of mankind, standardization has existed in one form or the other. The necessity of standardization was felt during the Second World War when the Allies could not get the war equipment of interchangeable nature. All these resulted in the formation of International Standardisation Organization (ISO) which has defined “ Standardisation” as: -

“ The process of formulating & applying rules for an orderly approach to a specific activity for the benefit and with the cooperation of all concerned & in particular for the promotion of optimum overall economy taking due account of functional conditions & safety requirements”.

1.02 From both logistics and economic considerations, lesser variety of items purchased, stocked, transported and used by the services, the better the war preparedness and fighting fitness. Hence the “ Defence standardization” is defined as follows: -

“ It is a means to provide the use of minimum number of parts to serve the maximum number of purposes consistent with economical manufacture, minimum whole life cost and the quality/ reliability to ensure maximum fighting effectiveness”.

1.03 The basic aims of Standardisation are: -

- Variety reduction of existing inventory.

- Effective means of Entry control

- Laying down procedures, methodology and guidelines that result in saving of time, money and resources

1.04 Defence Standardisation Organisation

1.04.01 Directorate of Standardisation is responsible for conducting standardisation activities in all fields in Ministry of Defence under the control of Department of Defence Production within the broad policies formulated by Standardisation Committee. For efficient functioning, Directorate of Standardisation is required to interact with various organizations/agencies within/outside the Ministry of Defence such as Army, Navy, Air force, DGAQA, DGQA, DRDO, OFB, Defence PSUs and BIS etc.

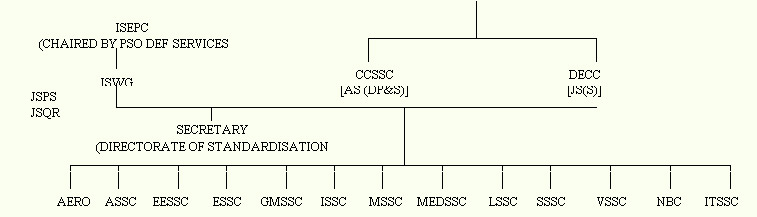

1.04.02 The organization structure of Defence Standardisation is as under: -

ORGANISATION STRUCTURE OF DEFENCE STANDARDISATION

1.05 Philosphy of the Preparation of Standardisation Documents

1.05.01 Two important activities of Directorate of Standardisation as mentioned in the policy Directive are:

- Entry Control

- Variety Reduction

1.05.02 To achieve “ Entry Control” the Directorate prepares Joint Services Catalogues based on NATO Codification system. Catalogues are being published group-class wise and circulated to all concerned AsHSP and the secretaries of the Standardisation sub-committees. When a new store/item is introduced in to the services these catalogues are checked through Computers Media to prevent duplication thereby ensuring “ Entry Control”.

1.05.03 To acheve Variety Reduction, the following types of Standardisation documents are prepared:

- JSPR

- JSRL

1.05.04 Secretaries are required t oprepare a Joint Services Preferred Range (JSPR) of a list of stores based on Catalogues of a particular commodity/equipment/ assemblies /sub assemblies/item belonging to a specific discipline like Armament, Electronics etc. Similarly JSRL are prepared to ensure “Variety Reduction”. Further, Joint Services Specifications are prepared to ensure for a particular store, or Indian Standards (IS) is adopted based on the JSPR and JSRL already prepared in a particular group class of stores/items. However, it is not possible to prepare JSPR, JSRL and JSS etc. or various stores held by the services. The Secretary is required to prepare the standardisation documents in the order of JSPr, JSRL and JSS to the extent possible.

1.06 Standardisation Committee

1.06.01 The Standardisation committee is the foremost policy making body on all matters pertaining to Standardisation. The Directorate of Standardisation provides the secretariat for the Standardisation. The Directorate of Standardisation provides the secretariat for the Standardisation Committee. The committee lays down the policy guidelines concerning standardisation and other matters within the scope of standardisation directive.

1.07 Committee of Chairman Standardisation Sub-Committee

1.07.01 There are thirteen standardisation sub-committees each headed by a chairman from different organisations to progress the activities on preparation of standardisation documents based on five year roll-on-plan. The committee also lays down the norms for the preparation of standardisation documents and adoption of Indian Standards.

1.08 Standardisation Sub-Committees

1.08.01 To assist the Standardisation Committee in implementation of the policy, Standardisation Sub-Committee with adequate and appropriate representation of the Services, R&D Organisations, AsHSP, OFB and concerned agencies have been formed. There are thirteen sub-committees as under:

- Aero stores standardisation sub-committee (Aero SSC)

- Armament standardisation sub-committee (ASSC)

- Electrical standardisation sub-committee (ESSC)

- Electronic standardisation sub-committee (LSSC)

- Engg. Equipment standardisation sub-committee (EESSC)

- Guided Missiles System & Components standardisation sub-committee (GMSSC)

- Instruments standardisation sub-committee (ISSC)

- Material standardisation sub-committee (MSSC)

- Medical Stores standardisation sub-committee (Med SSC)

- Stores standardisation sub-committee (SSSC)

- Vehicle standardisation sub-committee (VSSC)

- Information Technology standardisation sub-committee (ITSSC)

- Nuclear Biological & chemical standardisation sub-committee (NBCSSC)

1.09 Technical Panels: To assist sub-committees, Technical Panels have been created. Authority to form the technical panels rests with the Chairman of the standardisation sub-committee.

1.10 Working Groups: The Chairman of the standardisation sub-committee and Technical Panel may constitute Working Groups within the sub-committee/Technical Panels for progressing specific standardisation tasks which need expert and detailed study. Such Working Group will be dissolved on completion of the assigned task.

1.11 Defence Equipment Codification Committee (DECC)

1.11.01 DECC was set up by the Government of India to give a practical shape to the principles of standardisation and codification of defence stores. The committee is the paramount body dealing with codification and cataloguing activities of Defence stores on uniform basis. Committee functions under the Standardisation Committee, which is the Apex body that lays down the broad policies.

1.12 Benefits of Standardiastion: Some of the benefits that accrue out of standardisation are:

- Reduction in inventory

- Ease in design, production & procurement

- Ease in inspection

- Enhancement of interchangeability, reliability, safety & maintainability

- Uniform supply language between producer, purchaser, inspector &user

- Bulk procurement and overall economy

- Results in saving of time

DEFENCE STANDARDISATION CELLS UNDER DIRECTORATE OF STANDARDISATION: ROLE & RESPONSIBILITIES

Introduction

2.01 The Directorate of Standardisation in the Ministry of Defence is responsible for taking all measures regarding Standardisation of Defence Stores. This Directorate has been functioning under the Department Production since 1962. The tasks performed by this Directorate can be summarised as under:

- Codification of complete Defence Inventory as per Defence Codification System (Please see the Codification Manual also).

- Preparation of standardisation documents including Joint Services Specification, Joint Services Rationalised List, Joint services Preferred Ranges and Joint Services Guides.

- Effective means of entry control and variety reduction of existing inventory.

2.02 Codification of Defence Equipment can be described as the evolution and employment of a code or a system that uses an uniform pattern of numbering the items and denoting each item by a well defined scientific nomenclature, which will uniquely identify a store/item when so referred to. Codification is a pre-condition for developing Defence Catalogues and a database for entry control, Standardisation and rationalisation /variety reduction. Codification followed by standardisation results in enormous savings identification of items and management of procurement on a planned basis in the Services.

2.03 In order to finalise any Standardisation document, considerable work has to be done by way of getting complete details, method of manufacture, and details of material and testing procedures. Directorate of Standardisation does not have machinery of its own to obtain these results. It has, therefore, to be dependent upon the agencies of the Directorate General of Quality Assurance who are responsible for maintaining specification of Defence Inventory items known as the Authorities Holding Sealed particulars (AsHSP). Further manufacturers and establishments of Defence Research and Development Organisation are also the source from which the Directorate of Standardisation obtains are also the sources from which the Directorate of Standardisation obtains the particulars required for the preparation of standardisation documents. The AsHSP who function under the control of DGQA are spread throughout the country and functionally divided on the basis of the specific discipline/equipment they deal with. Thus, there are separate AsHSP for vehicle, for materials and for electronic items etc. The Directorate of Standardisation has t orely on this machinery for obtaining the required for prefacing the standardisation documents. Similarly, the AsHSP of Air Force and Navy are also located at various Nodal points of the country that are to be approached for getting necessary technical information on the Defence Stores they deal with.

2.04 The Directorate of Standardisation did not have any staff stationed in the AsHSP for collecting the information required for this purpose of preparation of Standardisation documents and Catalogues. Accordingly, Nine Standardisation Cells under Director, Directorate of Standardisation at New Delhi, Bangalore, Pune, Jabalpur, Calcutta, Madras, Kanpur, Dehradun and Secunderabad covering all the AsHSP have been established.

DUTIES OF DEFENCE STANDARDISATION CELLS

2.05 The Standardisation Cells perform the following functions:

- To maintain a clase liaison with the respective AsHSP and coordinate various Standardisation activities as per directions form the Directorate of Standardisation.

- To scrutinise new introductions to the inventory and advice the AsHSP in case the items do not conform to existing standards.

- To liaise with R&D Organisations in order to provide information in respect of standardisation documents and thus help the R&D to implement standardisation right from design stage.

- To monitor, and ensure the implementation of the standardisation documents and provide necessary feed back to the Directorate of Standardisation.

- To liaise with AHSP regarding queries raised by Directorate of Standardisation on items projected by AHSP for codification.

- To periodically examine the existing inventory/equipment/stores and forward recommendations on their selection for preparaing standardisation documents to the concerned Secretary, Standardisation Sub-Committee.

- To liaise with local Defence Organisations/PSUs and obtain technical assistance required for preparation of standardisation documents.

- To obtain stock samples locally available with AsHSP/User Unit of Defence required for preparation of standardisation documents.

- To carry out the codification work as allotted form time to time by Directoate of Standardisation. The details pertaining to codification forms/instructions can be had from Codification Manual/Defence Standardisation Cell.

- To provide all necessary input for updating cleaning the draft codified list of stores.

- To carry out continuous review of Catalogues/Standardisation documents in order to update them from time to time.

- To liaise with nearest/local AHSP, PSU, DRDO Laboratories/Establishments and private sector for getting necessary information pertaining to codification activities and if necessary, to forward the DCA-11 forms to Directorate of Standardisation, after carefully vetting them.

- To maintain liaison with BIS in respect of Defence Stores for which

- To prepare initial drafts on Joint services Specifications/Rationalised Lists/Preferred Ranges on items allotted by the Secretary Standardisation Sub-Committee as per approved Roll on Plan.

- To carry out continuous review of standardisation document and departmental specifications with the object of convering them into joint Services Specifications as and when required.

- To keep abreast with Technical information regarding the International and National Developments in the fields of Standardisation.

- To undertake any specific tasks whenever allotted Directorate of Standardisation.

STANDARDISATION DOCUMENTS

3.01 Standardisation sub-committee is responsible for the preparation of the following type of documents:

- Joint Services Specifications

- Joint Services Preferred Range

- Joint Services Preferred Range Rationalised List

- Joint Services Guide

- Approval Notification

3.02 Joint Services Specifications

3.02.01 JSS is a specification which is peculiar to Defence use and contains a concise statement of a set of requirements to be satisfied by a product, a material or a process indicating appropriate procedure by means of which it may be determined whether its given requirements are satisfactory.

3.02.02 Joint Services Specifications are Government documents prepared by the various Standardisation Sub-Committee with the help of Technical Panel/Working Groups (wherever applicable). These documents are mandatory for adoption in Defence as per Government of India letter No.86546/32/Std dated 06 Feb 1982. Whenever the Ministry approves such a document, use of the departmental specification in respect of the same item/components/equipment/material etc. if existing, will cease department, branches, cease forthwith. Sub Committee who drafts the specification ensures that the services, department, branches, establishments and other agencies involved in the preparation of necessary, members form the agencies outside the Sub-Committees should be co-opted to participate in the deliberations of the meetings of the panel/sub-committee. It is essential that the members of the sub committee/panel ensure that they have considered the views of all concerned branches or the department they represent. More frequent meetings of the sub-committee/panel should be conducted to sort out the differences in views of the participant members, if necessary.

3.03 Priority for Selection of Items

3.03.01 The purview of JSS are extended to all items/ stores/ materials/ processes/ procedures in Defence for which no Indian Standards are available or the existing National Standards could not meet the requirement of services. Joint Services Specifications are applicable to more than one service and while selecting items for preparation of JSS/Approval Notification, the following priorities will be considered: -

3.03.02

PRIORITY I

- High Cost/high volume common user items under indigenisation applicable to all the three services.

- High Cost/high volume common user items already indigenised applicable to all the three Services.

PRIORITY II

- High Cost/high volume common user items under indigenisation and applicable to two Services.

- High Cost/high volume common user items already indigenised and applicable to two Services.

PRIORITY III

- Balance of common user items under indigenisation and applicable to more than one service.

- Balance of common user items already indigenised and applicable to more than one service.

IMPORTANT NOTE: In all categories selection should start with those items which are going to remain longest in Service.

3.04 Joint Services Preferred Range

3.04.01 A preferred range of stores is a list of stores based on a series of preferred Numbers (such as Renard Series) and prepared out of a detailed analytical study of various aspects such as design expertise, technical know-how, production and inspection capabilities and user requirements. A preferred range permits the use of minimum number of sizes or grades' of an item to cover adequately the current and futuristic requirements. It helps in future design and development and aids in exercising effective "Entry Control" through standardisation by restricting the use of variety of components.

3.05 Joint Services Rationalised List

3.05.01 It is a list of items arrived at after the process of elimination of superfluous variety of existing inventory adequate to meet the prevailing needs of users at a given time. These are compiled to show the minimum number of different store necessary to fulfill the requirements of large varieties used by the user/services

3.06 Joint Services Guide

3.06.01 Joint Services Guide is a document issued by Directorate of Standardisation, which generally deals with miscellaneous subjects not covered by various standardisation sub-committees. These guides deal with both general and technical activities associated with standardisation discipline. In addition, the areas of the guide may include general guidelines on the selection of components, materials, finishes, surface treatment, preferred numbers and mathematical formulas, statistical methods associated with standardisation activity.

3.07 Approval Notification

3.07.01 Approval Notification is the adoption Indian Standards in full for use by Defence Services. Our National Standard is Indian Standard prepared by Bureau of Indian Standards. It is the policy of Government and the standardisation committee to adopt BIS standards where practicable in preference to making departmental specifications. If, it is adopted in full without any modification, the Directorate of Standardisation would issue Approval Notification. All procedures similar to the preparation of other documents are carried out before issue of Approval Notification.

3.08 Other Documents: JSPS and JSQR are very important documents, which form the basis of Standardisation documents. Once JSPS and JSQR on items/stores are issued then it is necessary to prepare JSS on those items/stores. Inter Service Working are formed by ISEPC for the preparation of JSPS and JSQR.

3.09 Joint Services Policy Statement (JSPS)

3.09.01 Joint services policy statement is prepared by inter services equipment policy committee (ISEPC). It lays down the development policy for a range of equipment / stores. It also covers the short term and long term requirements of the services in respect of design / development I procurement I user trails of the particular category of equipment/stores for use by the three services to meet their static and operational role.

3.09.02 JSPS covers the aspects such as ranges of equipment, their capacities, roles, value engineering, mobility, transportability etc.

3.10 Joint Services Qualitative Requirement (JSOR)

3.10.01 JSQR lays down the qualitative requirements of an inter-service equipment item and is a mutually agreed document between the ultimate user and the development agency.

3.10.02 JSQR covers the aspects such as proposed service employment, operational, technical / physical characteristics, value engineering, life expectancy, maintainability etc.

PROCEDURE FOR PREPARATION OF STANDARDISATION DOCUMENTS

3.11 Five year Roll on Plan

3.11.01 Five years Roll on plan is prepared in the month of Dec every year. It broadly indicates the subjects on which the Standardisation documents will be prepared in each financial year. This plan is formulated according to the policy directive issued. by Standardisation Committee. A five years Roll on plan thus prepared, is submitted to the chairman by respective secretary of each Standardisation Sub-Committee for discussion and approval. This five years roll on plan is reviewed and updated every year.

3.12 Preparation of Current Year Programme

3.12.01 From the five years roll on plan, the secretaries of standardisation subcommittees carefully review the current year programme and include or delete the subjects on which standardisation documents are to be prepared for the current year and the consequent years. After incorporating suggestions from the members of the subcommittee, the five years roll on plan is approved by the chairman. Each secretary of the Directorate forwards the finalised plan, approved by the sub-committee, to the technical coordination section. Technical Coordination Section consolidates and submits the five years roll on plan of all the sub-committees to Standardisation Committee for final approval.

3.12.02 The chairman of each sub-committee would also fix the annual target for preparation of standardisation documents for the current year, keeping in view the five year roll on plan and forward the same to technical coordinating section for approval by CCSSC and ratification by Standardisation Committee.

3.12.03 After the approval of the five years roll on plan by the Standardisation Sub-Committee the Chairman of each Standardisation Sub-Committee distributes the tasks to the panels/working groups/special technical panel for preparing the necessary standardisation documents.

3.13 Collection of Data

3.13.01 At appropriate time, the Secretary Standardisation Sub-Committee calls for and collects the data relevant to preparation of standardisation documents from service HQs, Stock Holders, AsHSP, Quality Assurance Establishments and other agencies including private and public sector. Concerned sections are to render willing cooperation by furnishing the necessary information for the fulfil1ment of this programme. Collection of data may require reference to such other sources as:

- Catalogues, vocabularies, rate books, or lists of items in stock

- Specifications, technical manuals, drawings purchase descriptions and other technical and statistical data used for procurement purpose.

- Current stock position and wastage rate.

- Continued requirements of the users.

3.14 Preliminary Analysis of Data

3.14.01 A detailed examination of the data is made by the Secretary, Standardisation Sub-Committee to determine the scope for standardisation. This examination may require physical inspection and comparison with other similar items under consideration and may also require reference to drawings related to them. When such occasions arise, the respective services will arrange to supply the sample stores to the members of sub-committee/panels/working groups as the case may be, at a place decided by the Directorate. Formal approval if required must be obtained by the service concerned before the stores are dispatched.

3.15 Assignment of the Task to the Technical Panel

3.15.01 The standardisation sub-committee in its meeting may decide to assign the task to a Specialist Technical Panel by inviting specialists in that particular field.

3.16 Convening of Technical Panel

3.16.01 Authority to convene a Specialist Technical Panel has been vested with the Chairman Standardisation sub-committee vide Government of India, MOD letter No. 86545/coord/std/8410/D(R&D) dated 16th Nov 1977. The convening order contains the following:

- Date and place where the panel will assemble

- Composition

- Terms and reference

- To whom and when the recommendations of the panel are to be submitted.

3.17 Composition of Technical Panel

3.17.01 The secretary of the sub-committee in consultation with the chairman invites nomination for the panel from the service HQs, Defence Establishments and public/private sector. This panel will then be composed after nominations are received.

3.18 Terms of Reference of Technical Panel

3.18.01 Directorate of Standardisation issues the terms of reference as approved by the sub-committee along with the composition to the members of the technical panel. Any amendment/deletion/change in the terms of reference/composition will be referred to the chairman of the sub-committee who in turn will discuss the changes in the subcommittee and will get the necessary amendment issued by the Directorate of Standardisation.

3.19 Time Limit for the Submission of the Final Document by Tech Panel

3.19.01 The technical panel progresses the task assigned to them with the help of Secretary of the Sub-Committee and other members. They will complete the task and submit the finalised draft standardisation document to the Standardisation Sub-Committee within the time frame allotted to them. In case the task is likely to continue beyond the stipulated date, the head of the technical panel will seek extension of the time limit from the chairman of the standardization sub-committee. The Chairman of Sub-Committee is empowered to decide the probable date of completion of the task in consultation with the members and will get suitable instruction issued by the Directorate of Standardisation to the head of the Technical panel.

3.20 Preparation of Draft Standardisation Documents by Regular Panel/Working Group

3.20.01 The members of sub-committee/panel/working group take decision as to what document JSPR/JSS/JSG are to be prepared and Indian Standards to be adopted. The secretary Panel/working group subsequently prepares the first draft document, which is circulated to the members of Panel/working group subsequently, prepares the first draft document, which is circulated, to the members. The draft is discussed in depth during the sub-committee meetings. Based on the deliberations a finalised draft document is prepared by the secretary.

3.21 Meeting of Standardisation Sub-Committee

3.21.01 After the circulation of the finalised draft a meeting of the Standardisation Sub-Committee will be called to discuss the task in detail. The members of the subcommittee are represented at appropriate level. They are vested with authority to take decision on behalf of those whom they represent to achieve speedy results. In exceptional cases, however the member may consult his parent organisation before any decision is finalised. Ally fresh issues arising during the sub-committee meeting will be taken up with standardisation committee meeting if no decision could be arrived at.

3.21.02 If, during the sub-committee meeting, the members of the Sub-Committee feel that the recommendation or any part of the recommendation of the working group requires a further detailed investigation to arrive at a decision, the task will be reassigned to them in accordance with the procedure given above.

3.21.03 Minutes of the meeting of the Standardisation sub-committee will be recorded by the secretary and issued to all concerned duly approved by the chairman. Minutes are to be issued as soon as possible after the meeting. Any amendments or additions to the minutes are to be accepted in consultation with the chairman.

3.21.04 When the Standardisation Sub-committee approves a document, the chairman and secretary will render separate certificates stating that all the members of the sub-committee have been consulted and all of them have agreed to issue the said document.

3.21.05 The chairman of standardisation sub-committee is responsible for meeting the target laid down for his sub committee.

HARMONISATION OF DEFENCE STANDARDS WITH INDIAN STANDARDS

INTRODUCTION

4.01 On the advent of 21st century the importance of Standardisation activity does not need any detailed explanation. "Standardisation Saves" is not merely a slogan but an established fact in our life. In India about 38 recognised governmental and nongovernmental agencies other than BIS are issuing standards for peculiar use by their related trade and industry in isolation. The more important among these agencies are: -

- Dte of Standardisation (MOD)

- Research design & standard organization (RDSO, Indian Railways)

- Dte of Marketing and Inspection (Agricultural Products)

- Central committee of food standards

- Drug Controller of India

- Chief controller of explosive

- Textile committee

4.01.01 The standards issued by these agencies regulate the particular sector of industry and service under their indict, These standards issued and used by these organizations are basically user standards as these standards are prepared keeping in view the end use, field of application, consumers interest and quality to suit the economy and departmental budget. On the other hand Bureau of Indian Standards serves as National Agency for industry standards in India related to products, software and services which offer the minimum acceptable quality level achievable by the Industry.

4.01.02 Harmonisation of standards, therefore, is an inescapable route that has to be treaded by all the agencies engaged in standardisation activities to ensure the dictates of world trade to over come the trade barrier resulting from the multiplicity of different standards used by different organizations or by different countries on the same subject or product. Harmonisation ensures inter-linking of technological developments and product improvement across world thus raising the quality of goods and services. In the present era of globalisation this has also become a reality due to unique advancement of information technology. In fact more and more acceptance of ISO Standards by different countries are an admission of acceptance of harmonisation of standards at International level.

Literary meaning of HARMONISATION is “Combination of pleasing and consistent whole free from disagreement or ill feeling". Analytically it is defined as "Combination of similar sub-sets to a universal set". Thus harmonisation consists of : -

- Combination of similar thoughts, activities, services or documents held by different persons, agencies, organisation or nation to a consistent, more meaningful and better version.

- The combination shall result in mutual benefit to the parties concerned.

- The combination shall be pleasantly agreed by the parties concerned.

4.02 Benefits of Harmonisation. The benefits that accrue out of harmonisation are: -

- It helps in a systematic transfer of technology through medium of standards.

- It raises the quality level through implementation of harmonized standards.

- It helps in orderly growth of industries in specific sectors especially export oriented industries and brings about International competitiveness in trade.

- It brings about an awareness in the industry' to the international quality level of products, process, test methods, system of coding etc.

- It makes available the products of international quality.

- It also enables test laboratories to make infrastructure that are state of art and at par with testing facilities of the world.

4.03 Areas of Harmonisation

- Chemical: Paints & allied protective and adhesives. Insecticides etc.

- Electrical: Motors, Relays, Switches, Connectors, Generators, Wire and Cables, lamps

- Electronic: Measuring Equipments, Regulated Power Supply Units, Signaling and Communication Aids, Audio Visuals and Computers, Papers (Telegraphic and Computers)

- Engineering: metal and Wood Cutting Machines, Fire Fighting Equipment, Compressors, Pumps, Air-conditioning and Refrigeration, Construction Equipment.

- General Stores: Fasteners, Hand tools (non power driven), Timber & Timber Products, Packing Materials, utensils.

- Instruments: Photographic and Optical Instruments, Time measuring, Surveying and Drawing Instruments, Recording, Controlling and Analytical Instruments, Scales & Balances, Meteorological Instruments.

- Metallurgy: Forging, Castings, Welding, Abrasives, Quality Control of Ferrous and Non Ferrous Metals.

- Medical: Hospital Equipment and Chemicals, Bandages etc.

- Petroleum: Fuels, Lubricating Oils and Greases Products.

- Textiles: Cotton Wears, Woolen (Woven &knitted), Ropes, Tents etc.

- Vehicles: Head Lights, Tyres and Tubes, Filters, Clutches, Wheel Rims, Radiators etc.

4.04 Harmonisation of Defence Standards with Indian Standards. Directorate of Standardisation took initiative in the field of harmonisation by interacting with BIS to harmonise Defence Standards with Indian Standards. After preliminary discussions and meetings an action plan was drawn and Harmonisation Sub-Groups were formed in Directorate of Standardisation. They were responsible for collection and scrutiny of Defence Standards against existing IS Specifications. They were also responsible to interact with Division Councils of BIS and DGQA/DGAQA, AsHSP, DRDO, DGOF and Services HQs for harmonisation activities. The procedure adopted for Harmonisation of Defence Standards with IS Specifications is shown in the following diagram: -

DEFENCE STANDARDS

SIMILAR INDIAN STANDARD EXISTS NO INDIAN STANDARD EXISTS

CODIFICATION

INTRODUCTION

Background

1.00 In any production organization, material costs account for approximately 50-60% of the total cost. Expenditure directly or indirectly connected with materials, therefore, emerges as a major area for cost reduction. Phenomenal success of Japan and USA in recent years can be attributed largely to effective management of materials. Simplification, entry control, rationalisation, identification and disposal of dead\obsolete inventory have become by-words in materials management.

1.01 There can be no comprehensive and meaningful discussion on material management in defence without taking into 'account various agencies like the R&D (research), the DGOF (manufacturer), the DGS & D (procurement & disposal) the 001 (inspection) and the three services (users) who constantly inter-act with one another on several aspects. Since so many agencies are involved, it is essential that a common supply language be evolved, which is uniformly understood by all concerned. Classification and codification of inventory thus form a powerful tool in this respect.

WHY CODIFICATION

1.02 Army, Navy and Air Force are using a large variety of equipment of varying complexity. Each equipment by itself consists of a number of assemblies, sub-assemblies and components. Since the equipment is supplied to the Armed Forces by foreign as well as indigenous agencies, it is possible that the same item is recognized by different names and numbers in the three services. Codification of defence inventory, therefore, becomes necessary to uniquely identify items on a uniform pattern.

1.03 Ideally an item should be identified by the same nomenclature and number (if allotted) throughout the country as in the case in USSR. Considering that jurisdiction of the Dte. Of standardization is limited to the defence organization, we have to perforce confine ourselves to evolving a system of codification for the defence establishments.

1.04 At present all the three services are following a system of codification catered to meet their own needs. All the systems by themselves are good and meet the requirements of each service individually but the system used by one service may not be completely applicable to the other two services. Moreover, in the standardization directive issued by ministry of defence on 05 Oct. 1977, the policy laid down with regard to codification and cataloguing is as follows:

"Service inventory shall be codified and catalogued under the defence stores cataloguing system. This will provide a uniform supply language for the three services. All new introductions shall be codified and catalogued in the first instance so as to avoid accumulation while the remaining services inventory will he catalogued on priority weighing".

1.05 It is in this backdrop that need is felt to evolve a common supply language i.e. nomenclature and number code for all the three services and other agencies connected with materials management in defence.

WHAT IS CODIFICATION

1.06 Definition of codification. Codification implies evolution and employment of a code or a system that uses uniform pattern of numbering the items and denoting each item by a well-defined scientific nomenclature, which will uniquely identify a store when so referred to.

1.08 Codification process. Codification process involves:

- Item identification. Identifying items on the basis of their characteristics, usage and manufacture and assigning an approved item name and description.

- Classification. Classifying them into appropriate classes in accordance with the system.

- Allotment of number. Assigning to them a unique item identification number, which is called defence stores catalogue (DS Cat No.) under the defence stores codification system. Cataloguing is the resultant activity of codification and involves besides the allotment of DS Cat No., arranging the items in a certain sequence to form a catalogue. The catalogue is essentially a list of items that are in use.

- Recording of identification data. Keeping a record of the identification data of all items codified and allotted DS Cat No. for compiling a catalogue and for checking whether a similar item has not already been codified.

METHODOLOGY OF CODIFlCATION

2.00 Introduction. The codification system adopted in our country for Defence stores is Group class reference cum characteristics system of codification. This system is based on NATO codification system, which is quite effective. This is tested and proven system originally developed in the US for Federal Supply items. Our Defence Stores codification system is a simplified version of the above system. This system adopted is known as the Item Identification Codification System (IIG) also known as Item Identification Supply Information System (ISIS). The main steps of system are as follows: -

- Selection of ltem Name

- Allotment of Group Class

- Item Description

- Checking Records

- Allotment of Number

- Recording of Data

- Intimation to initiator

- Issue of Catalogues

2.01 Selection of Item Name. An item name conveys the concept of a particular item of supply concerned e.g. Bolt Machine establishes the concept of a bolt, of a particular type. It also establishes uniform well-defined nomenclature, which is understood by all thus harmonising the inventory and acts as a first step in variety reduction.

2.02 Basic Name: - A basic name establishes the basic concept of the item. Such name consists of

- Either a single word (basic name) or a hyphenated name. For example :

CHAIR

SOCKET-SWITCH - Or a group of minimum number of word (Basic name phrase). For example: -

SEWING MACHINE

TERMINAL BOARD

2.03 A basic name may have one or two definitions in Codification Handbook IND-H6-l as an example to definitions of ADAPTOR given in Codification Hand book IND -H6-1 are reproduced below

- Mechanical: Any modifying part/piece of device designed to facilitate connection, provide accommodation, enable application and to broaden or permit the use of a given items with an unlike item of mechanical equipment when two items are not designed for direct mating to each other.

- Electrical. An item, which provides the necessary accommodation to electrically connect two or more items whose design or function, will not normally permit their connection. It may also provide mechanical connection.

2.04 In Codification Handbook lND-H6-1 some basic names are followed by numeral inside parenthesis. Such a numeral points to the applicable definition of the basic name. The parenthesis is not to be used in other documents such as catalogues, parts lists etc. For example:-

- ADAPTOR (2), ANTENNA OR TRANSMlTTER

2.05 Basic Name Modifier: - A modifier when added to the basic name, expresses the degree of differentiation necessary to restrict the item concept area established by the basic name to the more specific single item concept conveyed by the developed item name. For example:-

- SAW, HAND, CROSS CUTTING

2.06 Approved Item Name: - Approved item names are listed in capitals in codification Hand Book IND-H6-1. An approved item name consists of a basic name, which may be followed by one or two modifiers separated by a comma to differentiate between concepts items, each having the same basic name. For example: -

- COALTAR

- HANDSET

- ROLLER, BEARINGS

- PIN, STRAIGHT HEADLESS

2.07 Indian Name : - An Indian name is to be used under the following circumstances:

- An approved item name does not exists in codification handbook for an item. Normally this does not happen and a thorough checking of the codification handbook IND-H6-1 and IND- H2-3 is necessary.

- Certain colloquial names may not appear in codification handbook IND-H6-1 but the relevant approved item name may appear in a different form. For example: -

"SPLIT PIN" appears as "CLIP RETAINING". - Sometimes Indian Name is considered more appropriate for an item than its British name. Care is taken to ensure that foreign names are not thrust upon as a substitute for the popular Indian names e.g.

"TAWA" is more suitable than its equivalent name "PLATE BAKING PIE" given in the codification handbook IND-H6-1.

2.08 Colloquial Name: - A colloquial name is any name applied by Industry or a Government Department to an item for which an approved item name exists. Colloquial names published in IND-H6-1 are shown in running letters and are cross references to the, appropriate approved item name, e.g.

roller steel, anti friction see ROLLER, BEARING

2.09 Manufacturer's Item Name: - A manufacturer's item name may be accepted only when the item is specially designed for its parent assembly by a manufacturer having no other application and a suitable item name is not found in the codification handbook IND-H6-1. For example, an item "Hanger Barrel" designated for carriage of 81 MM Mortar on a mule saddle is given the item name HANGER BARREL, which is the name given to it by the manufacturer.

2.10 Item Name Code:- Each item name is associated with a five digit item name code e.g. "CLAMP REPAIR PIPE" has an ITEM CODE 05071 indicated against its name in IND-H6-1. Code is to be used in the computer records for the purpose of data processing. Whenever an Indian name has been accepted and there is no NATO equivalent, an item name code starting with "I" is to be recorded by CACOSA and intimated to all concerned. In case an Indian name is used in lieu of British name, item name code of Codification Handbook is to be used. When a manufacturer's item name is accepted an item name code 77777 is to be used.

2.11 Allotment of Group Class. Having decided on the name and the name code of the item for the purpose of inventory management, the items are classified into 4 digit numerical classes. The first two digits represent class within that group. The entire range of defence stores has been divided into 90 groups represented as 10 to 99 and numbers 01 to 99 further ~des each group into classes.

2.12 The structure of Federal System of Codification (FIS) as per cataloguing Handbook IND-H2-1Mar 82 edition consists of 78 groups, which are subdivided in to 642 classes. A group of stores comprises of equipment stores of similar nature, function, structure and so on. Each class covers a relatively homogeneous area of commodities in respect of their physical or performance characteristics or in the respect that the items included therein are usually requisitioned and used together or constitute a related grouping for supply management purposes

Examples of Group Classes

- Group 10 covers Weapons.

- GGroup 11 covers Nuclear Ordnance.

- Group class 1005 represents class 05 within the group 10 and covers Guns through 30 mm.

2.13 Use of cataloguing Handbook and codification hand book in determination of group class of an item. The publications necessary to be referred for the determination of group class of an item are

- Cataloguing handbook H2-1

- Cataloguing Handbook H2-2

- Cataloguing Handbook H2-3

2.14 Item Description. Having selected item name and GPCL for the item, next step in codification is to decided on the description of the item. All items can be uniquely identified only by their characteristics. The Dte. of Standardisation is codifying all the items of supply by generally specifying up to ten characteristics and five references. Less number of characteristics can be used provided the item is uniquely identified. This system is called as item identification guide (IIG) system and is fully explained later.

2.15 Checking of Records. The purpose of checking the record is to confirm whether any similar item has been codified earlier or not. This is required to ensure that dual part numbers ate not allotted to the same / similar item. This technique of checking is known: as REFERENCE CHARACTERISTCS MACHINING and is performed by computer. This requires special software, which has been developed by CACOSA of Dte. of Standardisation. Since it is not available to the AsHSP level, manual checking from relevant group class catalogue may be done before initiation a proposal for allotment of new part number.

2.16 Allotment of DS Cat Part Number. After getting confirmed that the item was not codified earlier a unique number is given to this item. This number is known as Defence Stores Catalogue Number of an item consisting of ten digits. In each DS class a six digits block of number starts from 000001 to 999999, thus providing for allocation of 999999 item numbers in each class.

2.17 Recording of Data. After allocating a unique number of supply, the data reference & characteristics of the item is stored in the computer files for future reference & to generate different types of catalogues.

2.18 Intimation to Initiator. The initiating agency is informed about the allocated number, along with characteristics/reference of the item of supply in the form of a report, called as DCDC report.

2.19 Issue of Catalogues. From the available data of codified items available following types of catalogues are prepared in order of priority for the usage of designer, manufacturer, supplier, quality assurance agencies and as basic decumbent for preparation of standardisation documents such as Preferred Ranges. Rationalised Lists to achieve variety reduction.

- Defence Equipment Catalogue

- Defence Assembly & Subassembly Catalogues (c) Defence Group Class wise catalogues

- Defence Equipment wise catalogues

- Defence Equipment stocking depot wise catalogues (for COD's)

ITEM IDENTIFICATION GUIDE SYSTEM

3.00 The codification system earlier followed was primarily based on the references only. This was not effective and possibility of duplication, resulting in item proliferation, was very high. More over for commonality establishment, a manual system existed. With the setting up of computer system in Directorate of standardisation, it was possible to start codification activities on "Item Identification Guide System"

3.01 IIG System.

- Item Identification. Under this codification system, the concept of each item of supply is fixed and expressed by item identification. The item identification consists of the minimum data required to establish directly or indirectly, the essential characteristic of the item, which makes the item unique, and differentiate from every other item of supply used by the services. The characteristics of item of supply are basically of two kinds:

- Physical Characteristics. Consisting of every thing that enters in to the make up of the item, such as its structure, material content, chemical composition, electrical data, dimensions, formation of arrangement of its parts, the principals of operation & like.

- Performance Characteristics. Consisting of the especial or peculiar kind of action or service provided by and expected of the item by virtue of its physical characteristics.

3.02 Item Identification Guides. These are the publications prepared by the UK Defence Codification Authority. They are used for codification purposes, to define the characteristics of an item of supply that need to be described to differentiation it from similar items of supply. Each no is a separate publication covering related groups of specific commodities. They are compiled on a basis of approved item names to which are applied a set of questions requiring answers giving the characteristics needed to identify the item. IIG system of codification provides ability to register, to catalogue, to search, to screen and to exchange coded characteristics data by means of automatic data processing.

FILLING UP OF REVISED DCA-11 (IIG) FORM

3.03 All the data activities for the item identification guide (IIG) system has been streamlined and any activity what so ever may now be governed by from revised DCA-11 (IIG) form or its simplified version Revised IIG form which can be used for obtaining any type of out put, information of any item, initial reference are characteristic screening, adding of data element or updating of data of item already codified, allotment of computer generator DS Cat No. (Defence Stores Catalogue Number).

3.04 The forms Revised DCA-11 (IIG) or its simplified version requires certain minimum information to be filled each time it is used, without which the (IIG) and revised IIG form will not serve any purpose. The Revised DCA-11 [IIG] and its simplified version Revised IIG form is placed at Appendices A & B respectively and it has the following information to be filled

- Input action code (IA)

- Submission Number (SUB)

- Action Element (AE)

- Data element Identifier code /primary address code (DEIC/PAC)

- Mode code

- Reply

3.05 Whenever a submission number is made for the creation of a new record, all efforts must be made to give the following references and DEICs/PACs

- References

- Manufactures name along with reference

- Suppliers name along with reference.

- Drawing /specification references

- AHSP reference such as ISPL or any other

- Parent system/main equipment/assembly/subassembly name & part number.

- DEIC

- Group Class (GPCL) - is to be given from H2-1/H6-1 Book it is purely numeric.

- Item Name Code is to be given from IND-H6_1 book against the item name selected. If an item does not appear in IND-H6-1 manufacturers name is identified and Indian INC is allotted by Dte. of Standardisation.

- Item Identification Guide: It is given in IND-H6-1 book against the item name selected.

- AHSP reference viz. code of AHSP to be mentioned.

- EIC (Equipment Item code) to be selected from

ME/AS/SA/CO/GP - Accounting Unit (AU) to be filled as allocated codes.

- Service User (SU) it is a single alpha character denoted L/N/A for Army, Navy & Air force and where S indicates for all the three services.

- PACS: In addition to the above references & DEIC, characteristics required as per checklist pertaining to item of supply must be provided in the form.

- Forwarding data: The data for codification of items is required to be sent by the initiating organisation in the following forms:

- Revised DCA-11 (IIG) form: for AsHSP and organisations holding catalogues hand books IND-H2-I, IND-H6-1, check lists and are trained to fill the forms.

- Revised IIG forms: for use by the organisations where trained staff for filling of DCA-11 is not available and all codification documents are not available.

- DEP: Ready to process Data Entry Package DEP in magnetic media to be used by the DS Cells in that area covering other AsHSP & other form initiation organisations.

- D Base Magnetic media IIG forms: IIG forms fields created in dBase by the sponsoring agencies keeping in view the field name created is kept same as shown.

Note: Each new activity must be initiated in a separate form DCA-11(IIG).

PRINCIPLES OF CODIFICATIONS

3.06 Codification is to be done for all indigenously manufactured equipment/accessories/ components of supply and in that order.

3.07 Only P items are to be codified

3.08 All-important equipment is to be codified irrespective of the mode of introduction. Assemblies/Sub-assemblies and components shall be codified. Only when indigenised.

CONTROL OF VARIETY

Introduction

4.01 Variety control is the voluntary elimination of unnecessary variety and formulating and applying rules to regulate variety. Variety occurs not only in products but also in parts, materials, tools, methods and processes and usually is the result of the influence of a number of factors One such factor is the pull of the sales department to persuade management to introduce new products, models or sizes. Another factor is the desire of certain individuals to impress their individuality on the products. A designer in his desire for individuality may design parts and use materials, which are slightly or just different from those in use.

4.02 Variety Reduction Includes:

- Elimination of unnecessary variety (simplification)

- Control of necessary variety (Standardisation)

- Concentration of efforts on selected range of products (specification)

4.03 Defence Standardisation is defined as "means to provide the use of minimum number of parts to serve maximum number of purposes consistent with economical manufacture, minimum whole life cost and the quality/reliability necessary to ensure maximum fighting effectiveness which can be achieved by:

- Effective means of entry control

- Variety reduction of existing inventory

4.04 Entry Control

4.04.01 Entry control through Standardisation shall be planned and implemented for preventing variety of items from entering the supply system. When one service wishes to introduce any item, it shall first relate to preferred ranges or Joint services specifications issued for similar items. When a service wishes to introduce an item dissimilar to that listed in a preferred range or joint services specification, it shall do so only after prior consultation with the Directorate of Standardisation. This is basically necessary to check the proliferation of the variety of the items. Further in case any item is available in any of the service, the utility of the same is to be checked by the service, which wishes to introduce the item. For effective entry control it is desirable to codify the entire current inventory.

4.05 Benefits of variety reduction

4.05.01 Variety generally increases cost and other organisational problems; it is, therefore, imperative to control the variety. Impact of variety reduction can be tremendous on company's profitability the benefits of variety reduction are

- Reduction in manufacturing cost

- Reduction in inventory investment

- Saving in purchase cost

- Effective advertising

- Reduction in direct labour cost

- Lower process rejection and improvement in quality

- Better machine utilisation

- Effective production planning and control

4.06 Areas of variety reduction

4.06.01 Variety can be reduced in every area: be it end products, components, materials, tools, supplies or even machine tools. Few major categories are:

- Variety reduction in end products> It at times proves to be the most rewarding area for cost reduction yet it is replete with lot of difficulties. Sales personnel raise a lot of hue and cry, if variety reduction is extended to the end products.

- Variety Reduction in Components: - A finished product is generally buildup from a number of components and if the final product cannot be standardised then it may be possible to standardise some of the components and sub-assemblies. A designer, therefore, must watch for unusual sizes and make products with parts, which already exist, and only as a last resort when nothing else is available should create a new part.

-

- Transfer work from one machine to another

- Achieve greater efficiency of maintenance function and operate with lower stock of spares.

- Maintain lower inventory of special tooling.

- Variety Reduction n supplies: - Standardisation can profitably be extended even to general supplies like erasers, carbon papers, soaps, lubricants, cutting tools etc.

- Variety reduction in bought out items: Variety reduction may be affected in standard parts and tools. The items which can be covered are:-

Bolts and nuts, screws, cutting tools, band tools, electrodes, oil seals. v-belts, bearings etc. - Variety reduction in raw materials: This should include specifications as well as sizes of materials.

- Variety reduction in maintenance supplies:- Considerable savings can be achieved by standardising maintenance supplies like lubricants (oil and greases) electronic supplies like wires, fuses, bulbs, contactors and switches etc.

4.07 Techniques of variety reduction

4.07.01 There are number of techniques/tools which are adopted by the organisation to effect variety reduction namely:-

- Income contribution analysis

- Frequency Analysis

- Preferred Numbers

- Rationalised Codification

4.08 Rationalisation

4.08.01 It is the process of elimination of superfluous variety of existing inventory adequate to meet the prevailing needs of the users at a given time. Rationalisation results in

- Elimination of certain types of items

- Change in quantity of each type of item

- Reduction in the total value of stock

4.09 Financial savings due to Rationalisation

4.09.01 Standardisation sub-committees are preparing JSRLs on various stores of inter service utility, where there is a scope of rationalisation. Therefore JSRLs prepared to effect rationalisation of a particular store should consider all the items already codified and listed in Defence Stores Catalogues. A lot of savings can be accrued through rationalisation. Financial savings due to rationalisation are:-

- Reduction in Capital tied up in stock

- Procurement of large quantity of items lead to quantity discount

- Reduction in number of orders

- Simplification in upkeep of stores

- Reduction in storage space

4.10 Matuura's Formula for Calculating Financial savings

4.10.01 Standardisation sub committees while preparing new JSRLs and revising the old JSRLs include all the current items in part 'A' and items rendered obsolescent/obsolete (as result of rationalisation/variety reduction) in Part 'B' of JSRL. Professor Matuura of Japan bas ably attempted a mathematical approach to variety reduction and its effects on economy. It helps in predicting the gains and the nature of benefits that might be expected to accrue from a given standardisation measure. He derived his mathematical formula on the basis of actual cost data which he collected from many different types of industries, the data related to the figures of cost before and after introduction of variety reduction of products.

4.10.02 Professor Matuura of Hosei University of Japan has developed the following formulae based on rationalisation, which has been found to be almost near to practical figures

-0.3

Y = X

Where Y = Fractional Unit Cost

X = Variety ratio

Original number of items

= -----------------

Reduced number of items

Percentage savings expected in unit cost = 1.0 - Y

Example:

(b) Variety Reduction: From 85 to 19

85

X = ----

19

= 4.47

-0.3

Y = (4.47)

= 0.64

Percentage savings expected in unit cost = 1.0 - 0.64

= 36%

4.11 The Defence Forces have a very large inventory and have tremendous scope for rationalisation and variety reduction. An enormous monetary saving can accrue to the Defence Forces and country.

Appendix ‘A’

REVISED DCA 11 (IIG)

DEFENCE CODIFICATION AUTHORITY

DIRECTORATE OF STANDARDISATION

FORM FOR INPUT TO / OUTPUT FROM DATA BASE

INPUT ACTION CODE

| I | A |

| S | U | B | D | D | M | M | Y | Y | Y | Y | |||||||||

AHSP

|

SEQ NO.

|

||||||||||||||||||

NAME

(AS PER INC) ________________________________________________________

| K | E | Y |

| A | D | D | R | G | N |

| A | D | S | P | C | N |

| A | D | A | U | T | R |

| A | D | S | U | P | R |

| A | D | G | P | C | L |

| A | D | I | N | C |

| A | D | I | I | G |

| A | D | A | H | S | P |

| A | D | A | U |

| A | D | S | U |

| A | D | O | N | U | M |

| A | D | P | R | I | C |

| A | D | Y | I | N | T |

| A | D | I | L | I | U |

| A | D | N | A | M | E |

Appendix ‘B’

REVISED IIG FORM

- INITIAL DETAILS

AHSP CODE

AHSP CODED D M M Y Y Y Y  SEQ No.

SEQ No. - INPUT ACTION

FOR NEW ALLOTMENT

FOR AMMENDMENT_____________________________________________ - NAME

- GROUP CLASS

- ITEM NAME CODE ME/AS/SA/CO/GP

(To be filled by DSC/AHSP) - CLASSIFICATION OF ITEM _____________________________________________________

- IMMEDIATE & END USAGE _____________________________________________________

- MANUFACTURERS NAME _____________________________________________________

- MANUFACTURER’ PART NO. _____________________________________________________

- SUPPLIER’S NAME _____________________________________________________

- SUPPLIER’S REF NO. _____________________________________________________

- SAHSP REF NO. _____________________________________________________

- SPECIFICATION (IF AVAILABLE) _____________________________________________________

- DRAWING REFERENCE _____________________________________________________

- OLD CODIFICATION NO. _____________________________________________________

- YEAR OF INTRODUCTION _____________________________________________________

- PRICE (AS ON DATE OF INITIATION) _____________________________________________________

- IN LIEU ITEM (IF KNOWN) _____________________________________________________

- ACCOUNTING UNIT _____________________________________________________

- STOCKING DEPOT _____________________________________________________

- CHARACTERISTICS _____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________ - SERVICE USER ARMY/NAVY/AIR FORCE

- COMPUTER STATUS CODE

- DATA TO BE UPGRADED

- DATA NOT TO BE UPDATED

- ITEM OBSOLESCENT

- ITEM OBSOLETE

- ANY OTHER INFORMATION USEFUL FOR CODIFICATION

- _____________________________________________________

- _____________________________________________________

- _____________________________________________________

- _____________________________________________________

- _____________________________________________________

- _____________________________________________________

DEFENCE STANDARDISATION NETWORKS

1.0 The phenomenal growth of the Internet and expansion of corporate Intranets throughout the world has resulted in an epidemic of browser mania. Conventional client database front ends including large database Projects are giving way to browser based applications. The incentive to adopt a web browser as a universal Gill is ubiquity; virtually everyone with a PC has at least some linking of browser based document display and navigation. Thus information technology managers expect to reduce user training costs and give computer illiterate top executives direct access to information from individual databases, data marts, and large scale data warehouses.

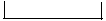

2.0 Directorate of Standardisation in order to speed up the process of Codification and Standardisation has set up a Data network at Centre for Advanced Computing and System Applications (CACOSA) interconnecting Data Networking Centre (DNC) and nine geographically separated Defence Standardisation cells. The two main LAN local area networks and the nine Dialup Networks have been inter connected through the DOT's packet switched network. The Standardisation Intranet uses TCPIIP for communication. A schematic diagram of the Standardisation network is shown below.

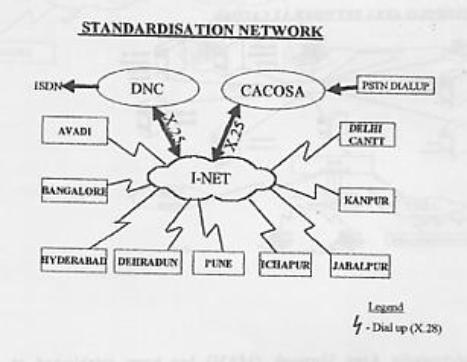

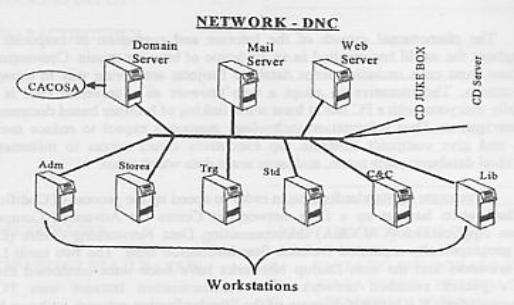

3. A Metropolis Area Network (MAN) has been established at each Defence Standardisation Cell The MAN servers provide for the database and SQL servers as well as the fire wall protection. This network has been established to facilitate the data access by the user agencies. Nodes of MAN have been provided with AsHSP and dial up connections configured. The server at each cell will have a mirror image of the central database such that the MAN, would facilitate data access to users in the local city area. The diagram representation of the network is shown below:-

4. The main facilities offered by CACOSA network are codification activities, E-mail and File Transfer. All these service are browser based keeping at par with the current technological developments in the field of IT. Web based data browse facility will be covered subsequently. The DNC network caters for universal access to National and International standards and specification pertaining to military and non-military products and services. This network also facilitates inter office video conferencing within the Standardisation HQs.

WEB BASED DATA BROWSE

5. This facility of data browse was developed recently and facilitates users to interactively browse the Codification Database. The various browsing options provided by this package are

Information based of DS CAT number

Manufacturer/Drawing number Details

Supplier Details

System Based Details

Year of Introduction Based

Common Items

Entry Control

Item Technical Characteristics

Specifications of Items

Obsolete Equipments

Variety Reduction

Price Negotiation

Substitutes

This package also provides the facility to customise the result screen by selecting only the required information and to download the Result of Queries.

ISO-9000

1. With the ushering in of the new industrial policy of Govt. of India, impact of liberalization and globalization, there is likely to be a larger interplay of the market forces bringing in its wake a competitive environment in the most sectors of the economy. To have a competitive edge, the company has to produce quality goods. Moreover, to be able to export, the company has to demonstrate that the quality of its products and services are of an Internationally acceptable standard. To achieve this, the organisations have to obtain a globally acceptable international standard IS0-9000.

BRIEF HISTORY

2. Various national standards have been developed in the past in the quality system arena for commercial and industrial use, and for military or nuclear power industry needs. The first attempt at the standardisation of quality systems was one of defence industry in the U.S.A through MJL.Q-9858 in 1959. Thereafter, a need was felt to adopt the quality system standards for commercial and industrial use. The solution for this came forth in 1979 with the publication of BS 5750 in Britain (U.K.). Simultaneously, a number of standards were developed in other countries, such as Denmark, Holland and West Germany. Some of these standards were guidance documents, whereas others were for contractual use between purchaser and supplier organisations. Despite some historical commonality in their heritage, these various standards were not sufficiently consistent for widespread use in international trade. Terminology in these several standards and in. commercial and industrial practice in various countries was also inconsistent and confusing. In 1987, ISO-9000 series of standards was developed to facilitate international trade and commerce. This series of standards was prepared by the International Standards Organization's (ISO) Technical Committee (ISO/TC 176) through the harmonization of standards in the U.S.A., Britain, Holland, Germany, etc. The publication of the IS0-9000 series in 1987, together with the accompanying terminology (vocabulary) standard (ISO-8402), has brought about harmonization on an international scale and has supported the growing impact of quality as a factor in international trade. The ISO-9000 series has quickly been adopted by many nations and regional bodies and is rapidly supplanting prior national and industry-based standards. ISO-9000 series of standards were revised in 1994 and the latest revision has been carried out in the year 2000.

ISO 9000 : 2000 SERIES

3. The ISO 9000 family of standards listed below has been developed to assist organisations, of all types and sizes, to implement and operate effective quality management systems.

- ISO 9000:2000 describes fundamentals of quality management systems and specifies the terminology for quality management systems. (This second edition cancels and replaces ISO 8402:1994)

- ISO9001 specifies requirements for a quality management system where an organisation needs to demonstrate its ability to provide products that fulfill customer and regulatory requirements and aims to enhance customer satisfaction. (This third edition of ISO 9001:2000 cancels and replaces the second edition ISO 9001:1994 together with ISO 9002:1994 and ISO 9003:1994. It constitutes a technical revision of these documents. Those organisations which have used ISO 9002:1994 and ISO 9003:1994 in the past may use this international standard by excluding certain requirements in accordance with 1.2)

- ISO 9004:2000 provides guidelines that consider both the effectiveness and efficiency of the quality management system. The aim of this standard is improvement of the performance of the organisation and satisfaction of customers and other interested parties. (This second edition of ISO 9004:2000 cancels and replaces ISO 9004-1:1994, which has been technically revised.

- ISO 19011 provides guidance on auditing quality and environmental management systems.

Together they form a coherent set of quality management system standards facilitating mutual understanding in national and international trade.

ISO 9000 : PHILOSOPHY/AWARENESS

4. The philosophy underlying is that ISO 9000 is: -

- A common sense

- Documenting all activities / operations and maintaining records for check

- A transparent management system i.e. management system by data or result

- For systematic working

- A tool for risk management

- For prevention rather than rectification

- A step towards TQM

NEED AND BENEFITS OF ISO 9000

5. The importance of ISO 9000 can be understood by the fact that more and more companies are adopting ISO 9000 series of standards. Some of the main reasons are:

- Global competition

- Trade with European Community single market

- Third Party Certification

- Quality as a competitive Weapon

6. Getting the ISO 9000 certification may be difficult but it is justified if one considers the benefits which accrue to the company Some of the benefits of ISO 9000 are given below: -

- Clarity of customer requirements

- Competitive advantages through ISO 9000 certification

- Clarity of roles and responsibilities

- Clear business objectives

- Control over the quality of operations

- Measurements of processes and the means for corrective action

- Assurance on the quality of suppliers and the products and services they supply

- Education and training of company personnel

- Adequate and maintained work instructions

- Effective working methods

- Independent audit of all operations

- An effective review of processes

- A framework for improvement

ISO 9000 REGISTRATION

7. The following ten steps plan is recommended for ISO 9000 registration: -

- Establish steering groups.

- Develop a strategic plan, which describes quality policy, vision, mission and goals.

- Establish a training plan

- One-day awareness programme for everyone

- Additional 2-day documentation programme for members of the steering group

- 2 day training for internal auditors IRCA, UK

- day for lead auditor IRCA, UK

- Review the existing quality system.

- Select appropriate ISO standard.

- Define, develop and implement the new quality management system.

- Develop a quality manual, establish procedures and work instructions.

- Develop self assessment capability.

- Make application for certification to certification body.

- Final assessment and certification

The registrar will audit your quality system with the help of documented procedures, instructions and quality manual. The registrar, on successful verification and assessment, will register the organisation.

8. Some of the terms associated with quality system certification have been explained below:

- Certification Body - An impartial body either governmental or nongovernmental, possessing the necessary competence and reliability to operate a certification system.

- Quality System Certification - The act of certifying by means of a certificate and or a mark of conformity that a supplier's quality assurance system complies with ISO 900 1, ISO 9002 or ISO 9003.

- Accreditation Body - A national body which evaluates the competence of the certification body.

- Accreditation -The formal recognition against a laid down criteria of the competence and impartiality of a certification body.

- Registration - The name of the supplier who is certified by a certification body would also appear in the register to be published annually by the Quality Council of India. The term "Registration" is used synonymously with "Certification".

COMMERCIALLY OF THE SHELF(COTS)

BACKGROUND

1. During the Second World War, there was a very strong campaign for standardisation of each and every product, item or equipment used by the Armed Forces of the Allies. Even the under garments worn by the soldiers, consumer goods & food products i.e. butter, the soap and any other paraphernalia used by the Armed Forces were standardised. Probably these was required at that time as the quality of products available through the general industry then were of much below the required standards and their failure during the War could translate the victory into defeat. The standards and specifications for the defense products started becoming more and more rigid in the post Second World War era.

2. The desire to have everything of Mil standard in the military increased the budgets to astronomical heights in the US as well as other countries. Despite huge budget for the Defence, what they could get was minimal due to very high costs involved in the production of a small quantity of equipment subjected to extremely high standards of specifications and standards.

3. Meanwhile, the quality consciousness among the masses had increased and the private industry also matured. They started adopting variations of Mil standards unto a certain level to improve the quality of their products. Increased awareness, consumerism and competition among the producers of the consumer products led to the development and availability of even high tech products of excellent quality at affordable prices. So, about a decade back there were plenty of brain storming sessions in the US forces to adopt to COTS (Commercial off The Self) items. The same has started affecting us since last 5 years or so.

WHAT IS COTS?

4. COTS stand for "Commercial off The Shelf' items. That means items, which can be picked up, form the open market and can be used for making defence equipment or a system or the item itself can be used as a system as a whole.

5. COTS may also be interpreted as the hardware and software that is used in a wide range of industrial applications and is available in broadly the same form, and to the same standard, form a variety of suppliers.

COTS AS A CONCEPT

6. In Military equipment/systems the electronic component requirements and Microcircuits are met through the MIL SPEC components. In the past few years due to constraints in foreign exchange and global non availability of MIL-Specification components due to either closing down of production line by major Military semi conductors suppliers or owing to obsolescence, there is urgency to evolve alternate strategies on MIL-SPEC components and identify equipment/system, based on its role where COTS components can be substituted.

7. The decision to change over/encourage COTS is aimed at moving the Defence procurement process away from the strict Regimental MIL-SPEC system that in many cases adds unnecessary costs to Defence contractors. By using COTS, the advantages found in the commercial world can be exploited.

8. COTS as a concept can be made applicable to cover every thing purchased by the Ministry of Defence (MOD) and its contractors form boots to integrated circuits. For commodity items like clothing, it is not difficult to see the logic in a less rigid, less costly commercial equivalent. However highly complex integrated circuits is a different matter.

9. The vast majority of purchases within MOD are for basic, standard, commercially available commodity products, soap, food nuts and bolts, fuel etc. It is clear that in these areas MOD can significantly reduce costs by purchasing commercially using standard commercial practices.